شرکت ساخت و تولید لوکوموتیو مپنا

درباره ما

در دهه 80 هجری شمسی در با اینکه صنعت ریلی در کشور عزیزمان ایران سابقه طولانی داشت، ولی اغلب تجهیزات و ادوات ریلی استفاده شده از خارج وارد میشد یا به شکل محدودی در ایران تولید میشد، شرکت مهندسی و ساخت لکوموتیو مپنا در چنین شرایطی تاسیس شد تا با انتقال تکنولوژی در صنعت ریلی، این خدمت عظیم را در اختیار مردم ایران قرار دهد.

+30

گواهینامه بین المللی در زمینه های مختلف

25+

محصول جدید و درحال توسعه در زمینه ریلی و جاده ای

1000+

متخصص در زمینه صنعت ریلی

1520+

هزار کیلومتر کارکرد لوکوموتیوهای تولید شده

شرکت مهندسی و ساخت لکوموتیو مپنا

خدمات

تعمیرات و بازسازی ناوگان

آمادگی ارائه خدمات در زمینه های تعمیر و نگهداری ، تعمیر اساسی و بازسازی انواع ماشین آلات ریلی

مونتاژ چرخ و محور

اجرای تعمیر اساسی مجموعه چرخ و محور (Wheel set) در انواع ماشینهای ریلی

رنگ

کابینهای سند بلاست، کابینهای رنگ برای قطعات بزرگ و سنگین و کابین رنگ برای قطعات و لوازم جانبی

شرکت مهندسی و ساخت لکوموتیو مپنا

سخن مدیرعامل

ما با ایجاد شرکتی دانش بنیان و ایجاد محیطی پویا و استفاده از ظرفیت متخصصان ایرانی برآن هستیم تا با تولید و ارائه خدمات تخصصی در حوزه لکوموتیو های باری و مسافری شاهد خودکفایی کشور در صنعت حمل و نقل ریلی باشیم و برند ایرانی را در این صنعت به دنیا معرفی نماییم.

محمدمهدی اسلامی

چشم انداز

ما تا سال ۱۴۰۴ به عنوان: رهبر بازار ایران در تولید و بازسازی باکیفیت انواع لکوموتیوها با تمرکز بر ایجاد خودکفایی در برآوردهسازی نیاز سالانه کشور، شناخته خواهیم شد.

شرکت مهندسی و ساخت لکوموتیو مپنا

محصولات

شرکت لوکوموتیو مپنا همسو با نیازهای کشور و هم تراز تکنولوژی روز دنیا محصولات ریلی را تولید و عرضه میکند، این محصولات با در نظر گرفتن نیازهای خاص بازار طراحی و تولید شدهاند.

شرکت مهندسی و ساخت لکوموتیو مپنا

اخبار و رسانهها

شرکت مهندسی و ساخت لکوموتیو مپنا

پروژهها

شرکت مپنا لکوموتیو با هدف توسعه سبد محصولات و پاسخگویی مناسب به تقاضای این بخش در بازار ریلی کشور و پیرو توافقهای پیشین با راه آهن جمهوری اسلامی ایران اقدام به تعریف پروژه طراحی و ساخت لکوموتیو باری MAP۳۰ با توان ۴۰۰۰ اسب بخار نموده است.

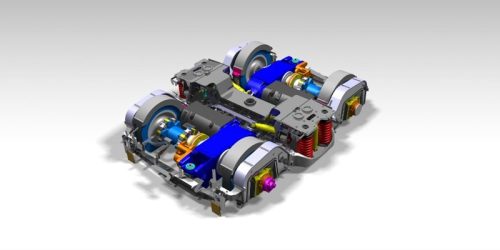

پروژه طراحی و ساخت بوژی لکوموتیو MAP۲۴، توسط شرکت مپنا لکوموتیو در سال ۱۳۹۳ آغاز شد. فرآیندهای طراحی با همکاری و مشاوره شرکت “ PROSE ” از کشور سوئیس اجرا شده است.

پروژه مهندسی و ساخت ۶ دستگاه لکوموتیو تونلی ۴۵ تن دیزل هیدرواستاتیک با توجه به نیاز کشور برای داخلی سازی لکوموتیوهای تونلی در پروژههای زیرساختی احداث مترو، در شرکت مپنا لکوموتیو تعریف گردید.

گروه مپنا درسال ۱۳۹۷ برندۀ مناقصه بازسازی ۵۰ دستگاه لکوموتیو آلستوم به کارفرمایی راهآهن جمهوری اسلامی ایران شد. این پروژه در قالب کنسرسیومی متشکل از شرکت گروه مپنا، شرکت تعمیرات و توسعۀ بهرهبرداری ریلی مپنا و شرکت مهندسی و ساخت لکوموتیو مپنا اجرا خواهد شد.

لکوموتیوهای GT۲۶ طی سالیان متمادی نقش مهمی را در صنعت حمل و نقل ریلی کشور ایفا نمودهاند. این لکوموتیوها به دلایل مختلفی از جمله سادگی طراحی سیستمها، عدم پیچیدگی سیستم کنترل، قابلیت مناسب سیستمها برای تعمیر و نگهداری، تأمین مناسب قطعات یدکی و همچنین سادگی استفاده از ادوات راهبری، مورد استقبال بهرهبرداران و تعمیرکاران ناوگان کشش ریلی کشور بوده است.